Drill Press is used for drilling holes in various materials. Drill presses allow you to drill holes in metal, wood and a variety of other materials more precisely and conveniently than you could with a handheld drill. Drill presses are precision tools, capable of boring holes in exact locations at carefully controlled depths. so you can use your drill press for such diverse tasks as sanding, mortising, buffing, grinding and shaping.

Drill press is an amazing tool. Machine tool for producing holes in hard substances. The drill is held in a rotating spindle and is fed into the workpiece, which is usually clamped in a vise supported on a table. Most drills have a variable speed feature, allowing the user to change the speed depending on the density of the material and the specific application. Speed can be adjusted via changing pulleys and belts. Drilling big holes usually requires a slower speed.

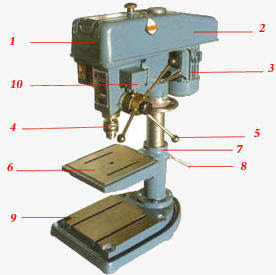

Drill press can also be used to drill holes in metal, plastic and other materials depending upon the speed of the motor (variable speed) and the drill bits used. With the right attachments. A typical manual drill press is shown in the figure below.

1. Top Cover - pulley safety guard (Case protecting the pulleys and the belt linking the motor to the drill.)

1. Top Cover - pulley safety guard (Case protecting the pulleys and the belt linking the motor to the drill.)2. drive belt and drive belt pulley

3. Motor

4. Drill Chuck (Device with jaws for attaching the bit or drill to the tool)

5. Feed Handle (Lever activating a mechanism for lowering or raising the chuck.)

6. table ( Flat surface whose height is adjustable; it supports the piece to be drilled.)

7. Column ( it supports the tool’s table, motor and head.)

8. table locking clamp (Locking device used to keep the table at a desired height.)

9. base (Support on which the tool rests, which can be bolted down to ensure maximum stability.)

10. Power Switch (Button for turning the device on or off.)

Safety tips for using drill press:

1. A power source with a voltage greater than that specified for the tool can result in serious injury to the user, as well as damage to the tool.

2. Using a power source with a voltage less than the nameplate rating is harmful to the motor.

3. Always be alert or aware where you are putting your fingers to avoid accidents.

4. Avoid wearing neckties or gloves when operating the drill press.

5. when operating the drill press, use safety equipment including safety goggles.

6. Periodically check that all nuts, bolts and other fixings are properly tightened.

7. Never use your hands to remove dust, chips or waste close by the drill bit.

8. Good housekeeping and operator training are absolute musts.

When you're looking for a drill press, compare the following:

| 120V, 60HZ, 2.5 amp 13mm max. drilling capacity 50mm spindle travel 46mm column diameter 5 spindle speeds: 760, 1150, 1630, 2180 and 3070 RPM Minimum 1" max. distance from spindle axis to surface of column 104mm maximum distance from spindle end Laser with FDA certificate Drill press price: $ 100 | |

| Drill Press, 3.2A, 3.2A Motor For Long Lasting, Smooth Performance, Adjustable Position, Locking Depth Stop For Accurate Depth Measurement & Repetitive Drilling, 1/2" Chuck Capacity For Better Gripping Of Accessories, Adjustable Work Light For Better Visibility, Tilting Table With Rack & Pinion Height Adjustment, Specifications: Amps: 3.2A, Speeds 5 (620-3100 RPM), 2 Year Warranty. Drill press price: $160 |